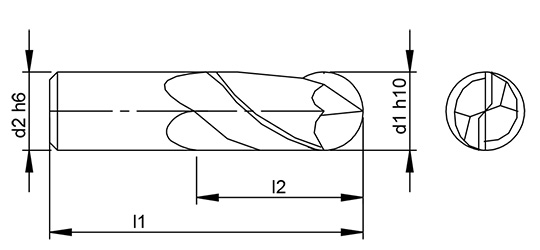

High Performance 2 Flute Solid Carbide Chamfered Endmill Range,HPC 2Flute Solid Carbide Chamfered Endmill Range,Designed for general milling applications where high metal removal rates are required and tool stability while cutting.

| Product Code | HP2 NWP |

| Application | Milling |

| Material Suitability | Steel, Titanium |

| d1 h10 | d2 | l1 | l2 | Z | Cx45¡ | Product Code Standard | Product Code Weldon Flat |

|---|---|---|---|---|---|---|---|

| 4s | 6.00s | 54.00s | 8.00s | 2s | 0.04s | HPC2-4.00s | HPC2-W-4.00s |

| 5s | 6.00s | 54.00s | 9.00s | 2s | 0.05s | HPC2-5.00s | HPC2-W-5.00s |

| 6s | 6.00s | 54.00s | 10.00s | 2s | 0.06s | HPC2-6.00s | HPC2-W-6.00s |

| 8s | 8.00s | 58.00s | 12.00s | 2s | 0.08s | HPC2-8.00s | HPC2-W-8.00s |

| 10s | 10.00s | 66.00s | 14.00s | 2s | 0.1s | HPC2-10.00s | HPC2-W-10.00s |

| 12s | 12.00s | 73.00s | 16.00s | 2s | 0.12s | HPC2-12.00s | HPC2-W-12.00s |

| 16s | 16.00s | 82.00s | 22.00s | 2s | 0.16s | HPC2-16.00s | HPC2-W-16.00s |

| 20s | 20.00s | 92.00s | 26.00s | 2s | 0.2s | HPC2-20.00s | HPC2-W-20.00s |

| 25s | 25.00s | 105.00s | 29.00s | 2s | 0.25s | HPC2-25.00s | HPC2-W-25.00s |

Please fill out your custom requirements if they are not listed above , one of our team will then get in touch with you.

High Performance 2 Flute Solid Carbide Chamfered Endmill Range,HPC 2Flute Solid Carbide Chamfered Endmill Range,Designed for general milling applications where high metal removal rates are required and tool stability while cutting.